Product Details

Overview

ZN63A(VS1)-12 Indoor high voltage AC vacuum circuit breaker (hereimafter referred to circuit breaker) isused in the three-phase AC 50Hz indoor place with the rated voltage 12kV as the protection and control of theelectrical facilities in the industrial mines, enterprises, power plant, and power substation, especially suitablefor mnetallurgy, chemical, and coal industries.Circuit breaker complies with the GB/T 1984 High Voltage AC Circuit Breaker, GB/T 11022 Commonspecifications for high-voltage switchgear and controlgear standards, DI/T 402 High Voltage AC CircuitBreaker, and related IEC standards.

The operating mechanism of circuit breaker is of the integrated design type. The operating mechanism andthe primary circuit are front and back anranged, and they can be used as fixed installation unit (fixed cabinet)and also for a cart unit (cart cab inet) together with the propulsion mechanism (chassis truck)

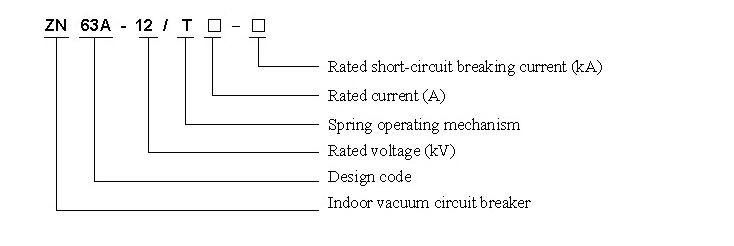

Type Designation

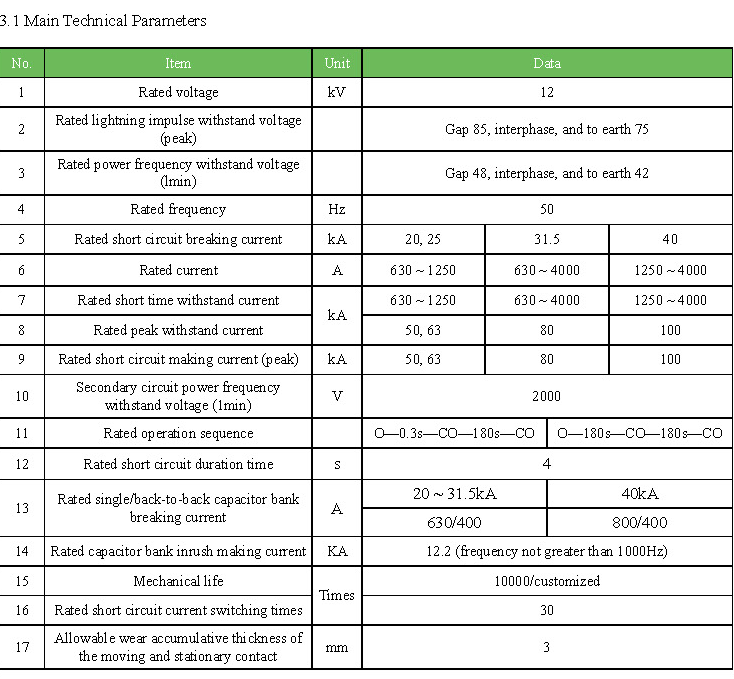

Technical Parameters

Operating Conditions

4.1 Normal Working Conditions

4.1.1 Ambient temperature: The max. temperature is +409C, and the min. temperature is -l 5eC (storage andtransport at -30°C are allowed),

4.1.2 Environmental humidity: The daily mean relative humidity is < 95%, the monthly mean relativehumidity is < 90%; the daily mean vapor pressure is < 2.2 x 10 - 3MPa, and the monthly mean vaporpressure is ≤1.8 x 10-3 MPa;

4.1 .3 The altitude does not exceed 1000m (customization is required if greater than 1000m),4.1.4 The earthquake intensity does not exceed 8 degrees;

4.1.5 There is no water drops, no flammable materials, no chemical corrosive gas and no severe vibration atthe site.

4.2 If the normal working conditions are not met, please contact the manufacturing unit.

Features

5.1 Excellent performance of circuit breaker

5.1 .1 The arc extinguish chamber and operating mechanism of circuit breaker are configured at front and rear,and are connected into a whole through the transmission mechanism.5.1.2 The mechanical life is not below 10,000 times.

5.2 The advanced vacuum arc extinguish chamber uses copper-chromium alloy contact and longitudinalmagnetic feld contact structure.

5.3 Enhanced insulating cylinder

5.3.1 The insulating cylinder is formed with new APG process.5 .3 .2 The inner skirt edge and reinforced ribs are provided in the insulating cylinder, improving the insulationlevel and dynamic stable current resistant capacity.5.3.3 The vacuum arc extinguish chamber is installed in an insulating cylinder to eficiently prevent damageand surface contamination due to foreign matters while shortening the overall size of circuit breakerobviously.

5.4 Flexible and simple operating mechanism5 .4.1 The operating mechanism is of the spring energy-storage type with electric and manual energy storagefunctions.

5 .4.2 When the circuit breaker is working, the energy from the en ergy-storage spring will be transferred to thelink m ech an ism through the output cam and th en to the dynamic contact through the link mechanism.5.4.3 With advanced and reasonable damping device, the break-brake rebound is small.5 .4.4 No adiustment is required with very little maintenance.

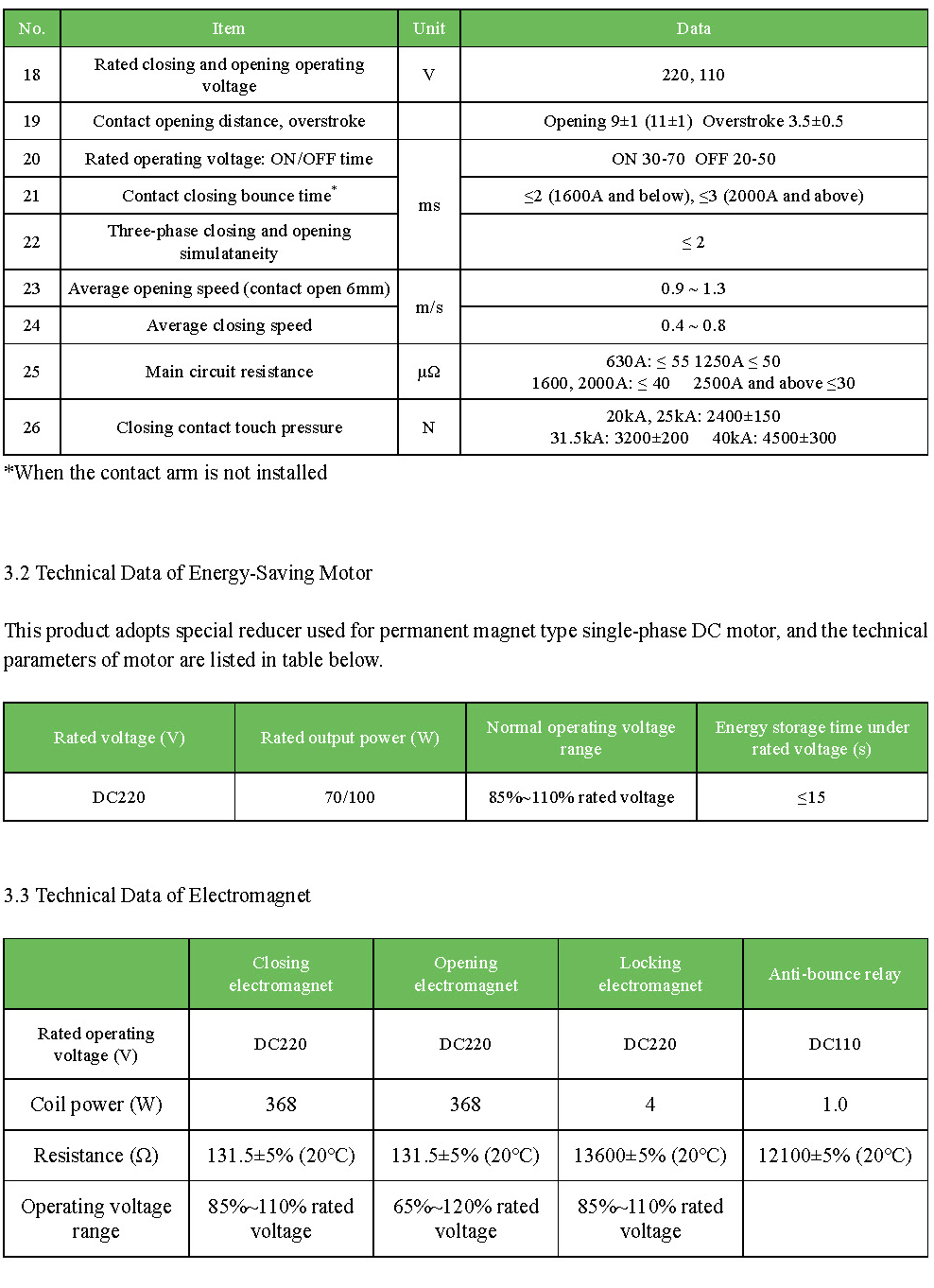

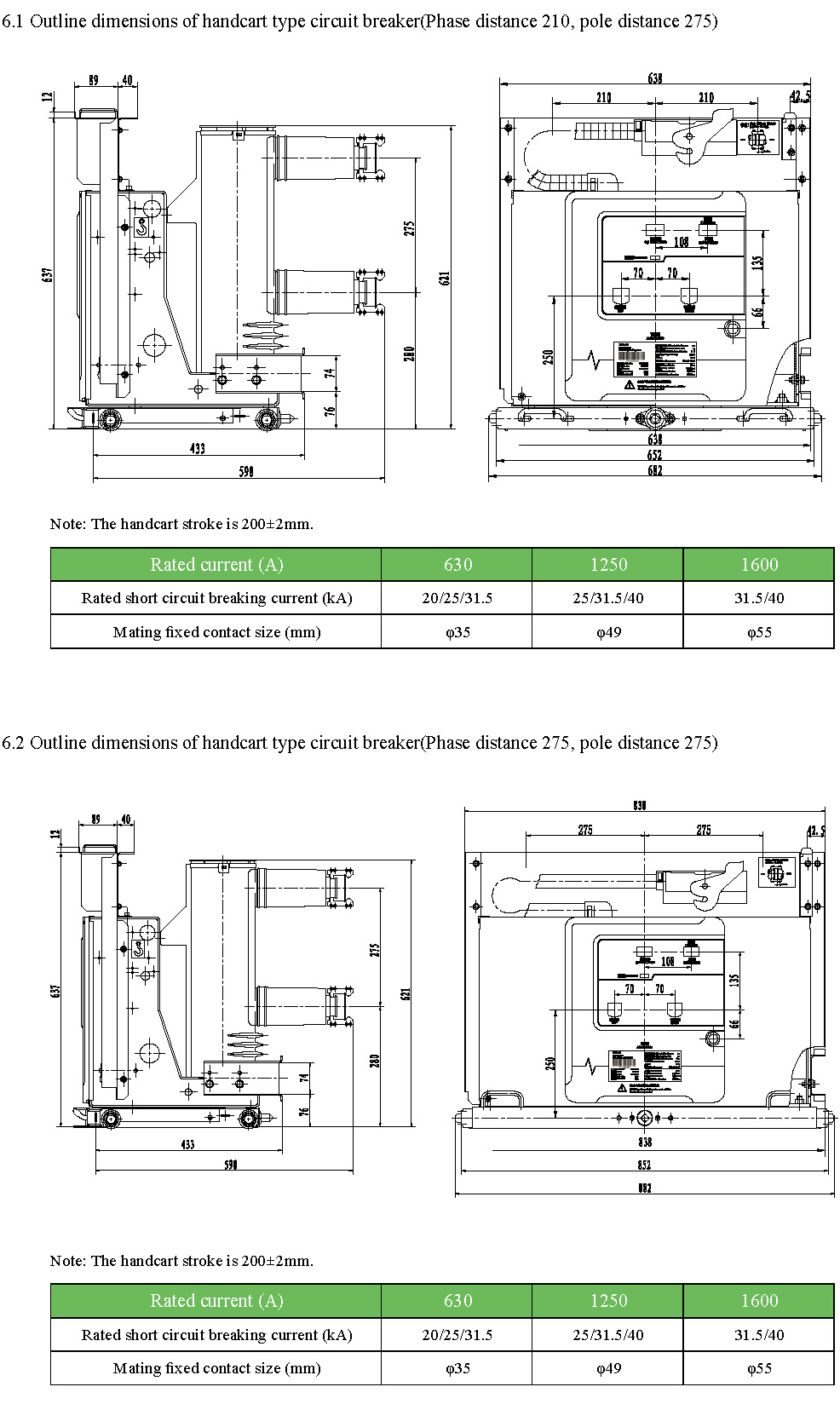

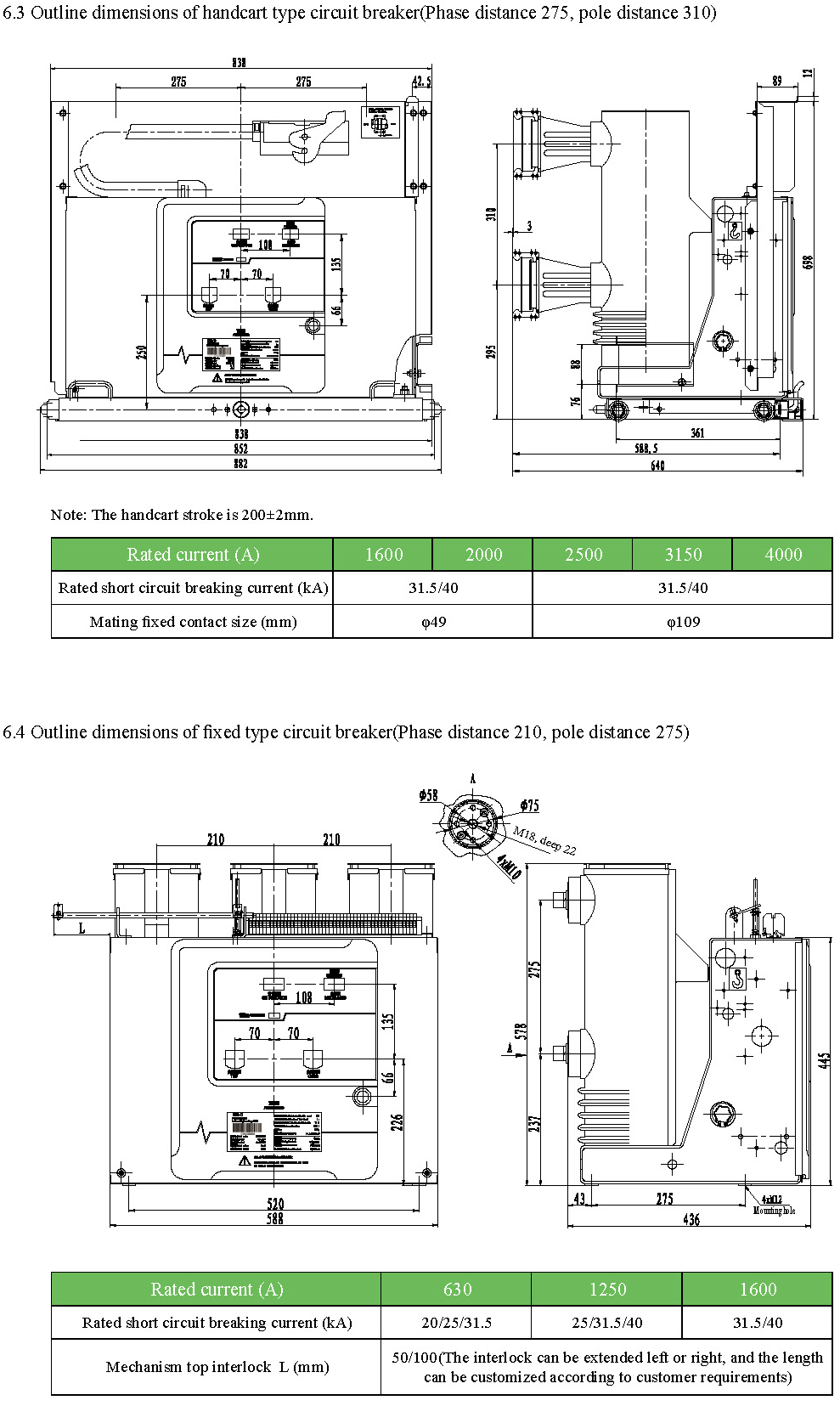

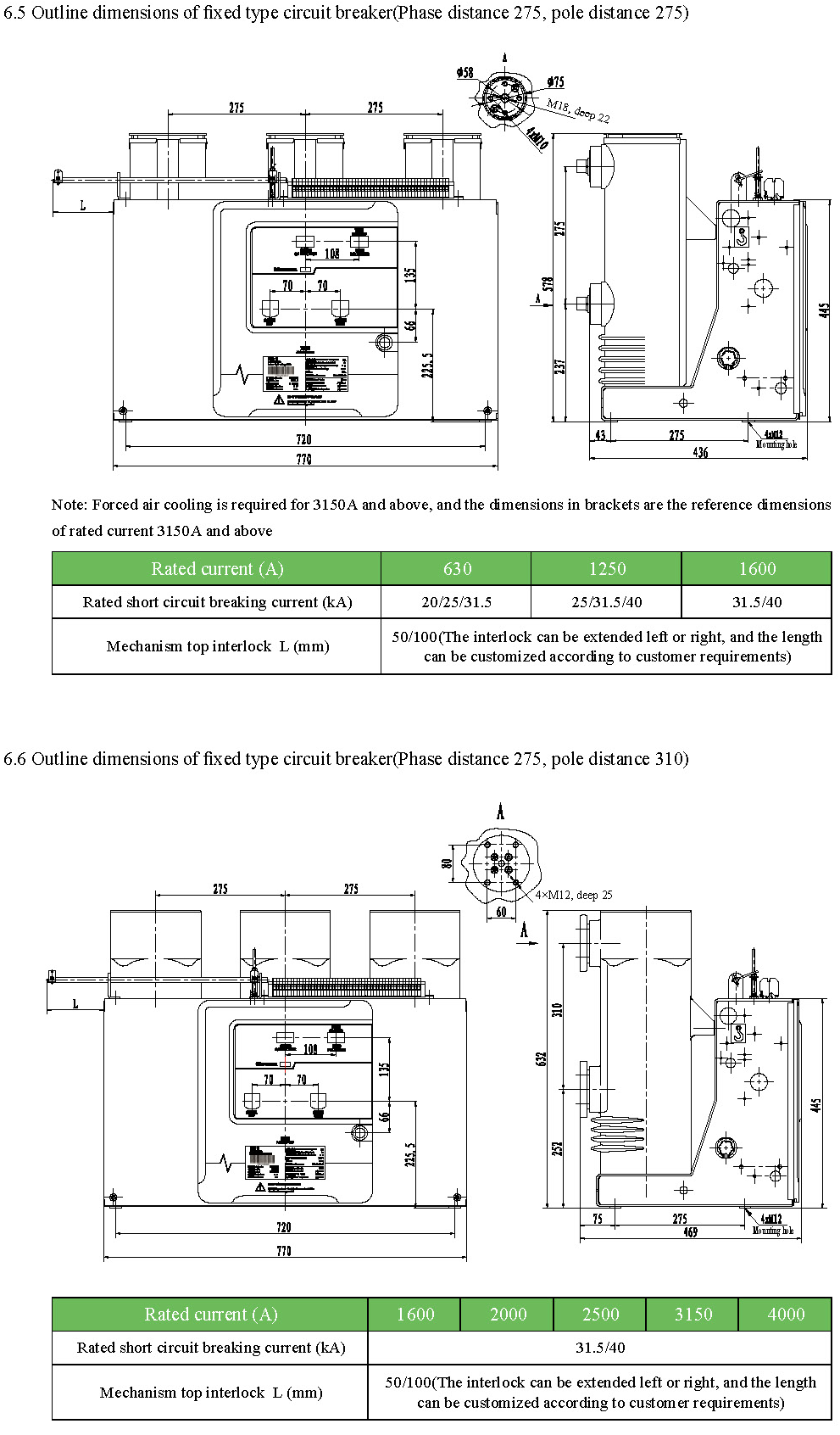

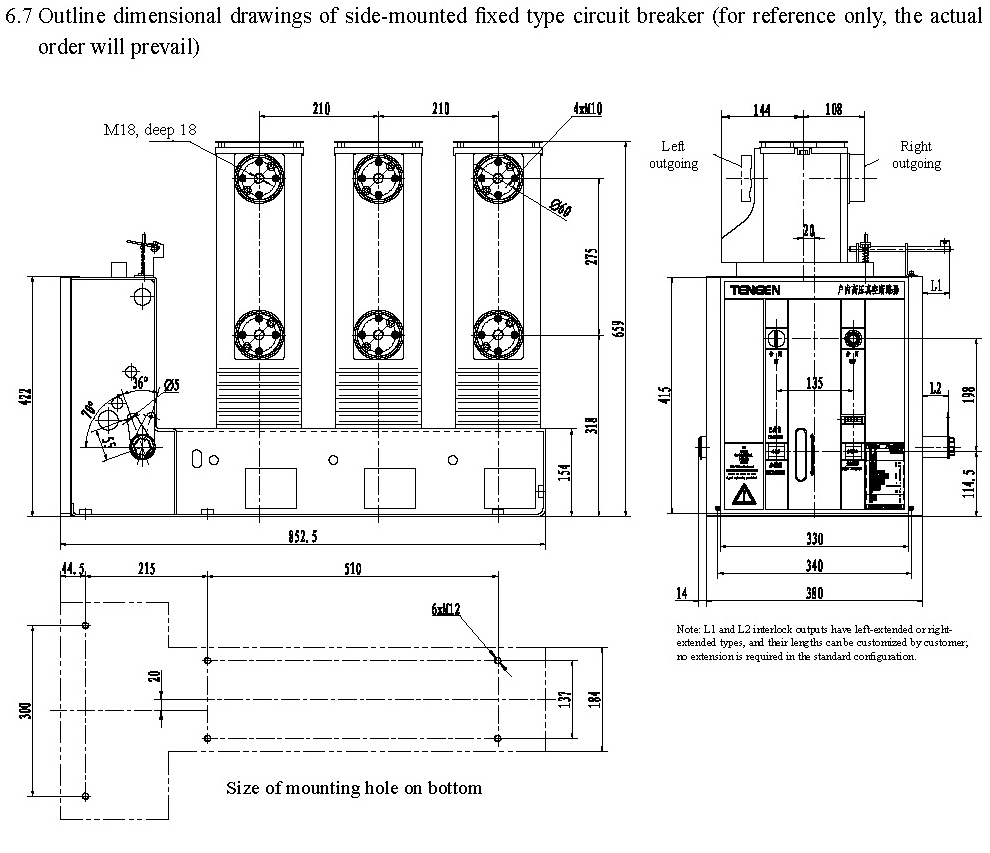

Outline and Installation Dimensions

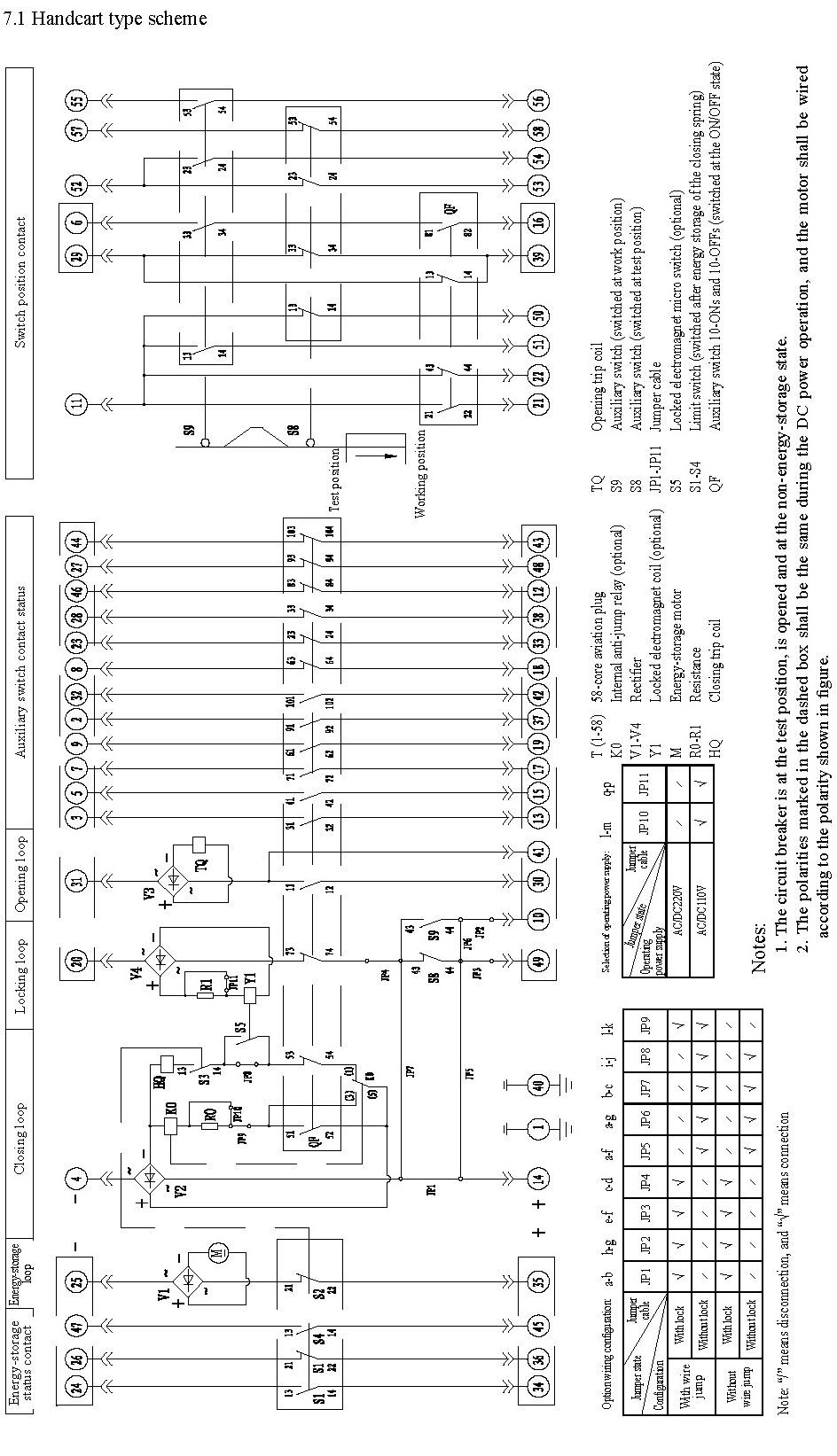

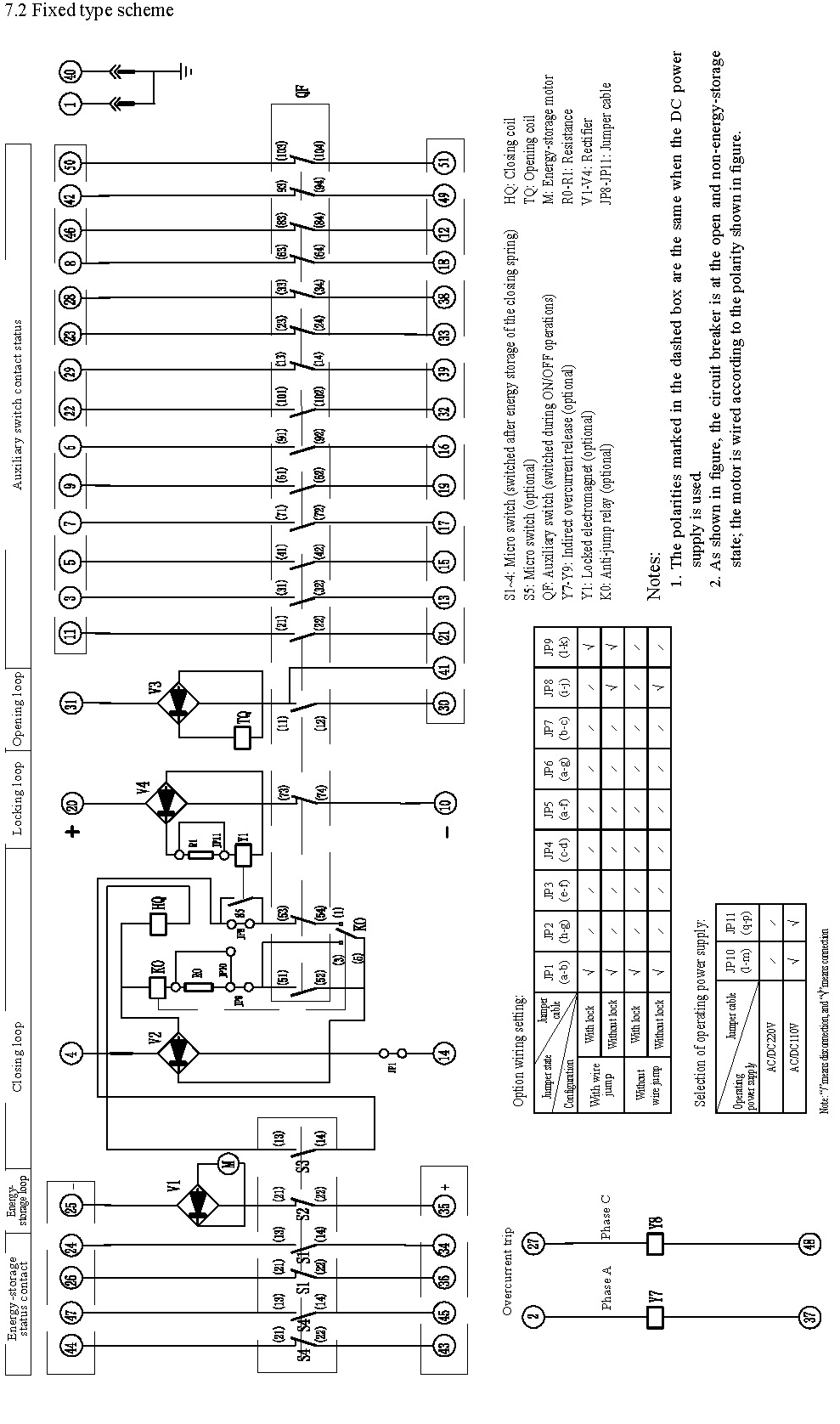

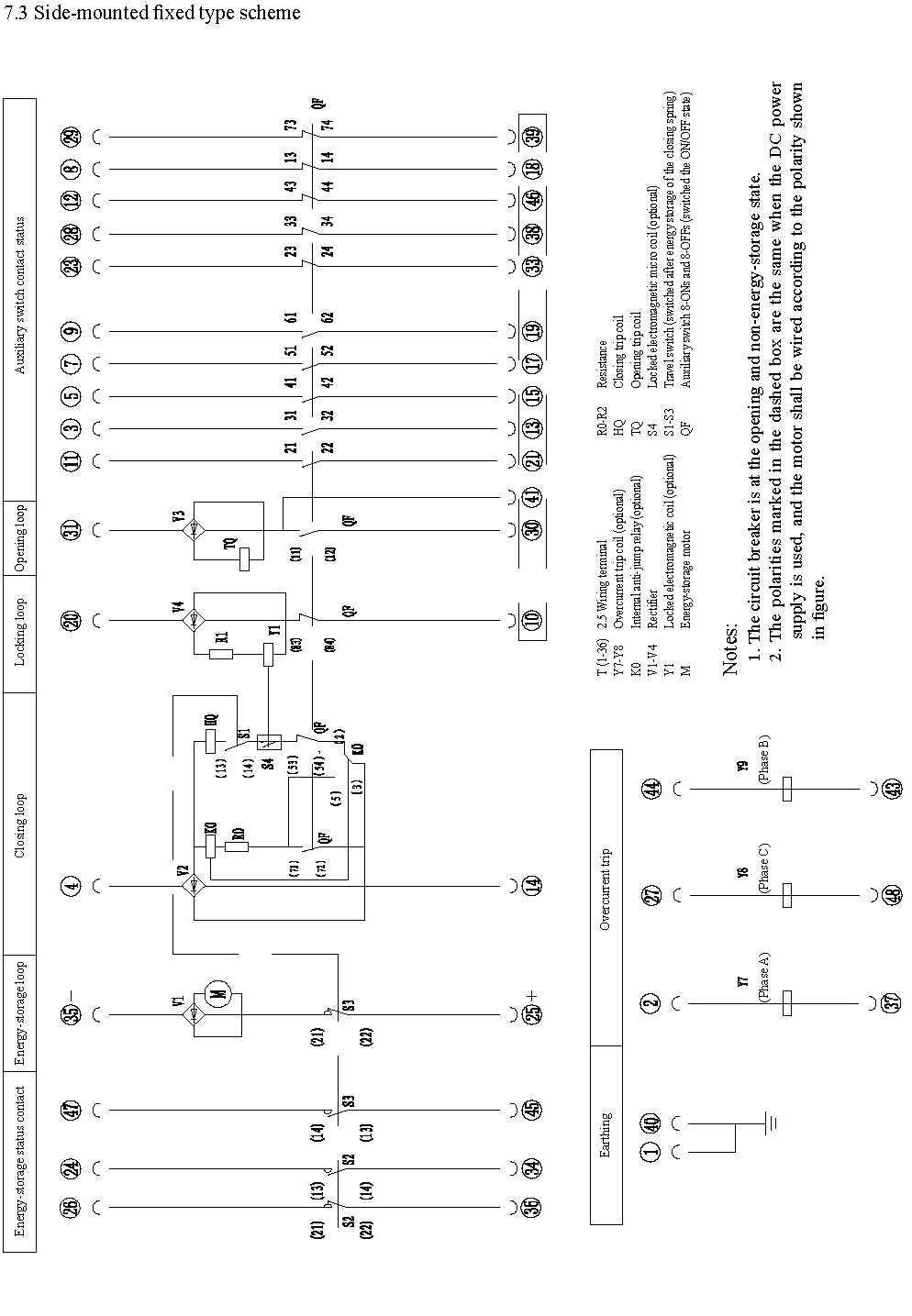

Secondary Scheme Schematic Diagram

Online Inquiry

Or use the inquiry form below. Our sales staff will contact you within 24 hours. Thank you for your interest in our products!